Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

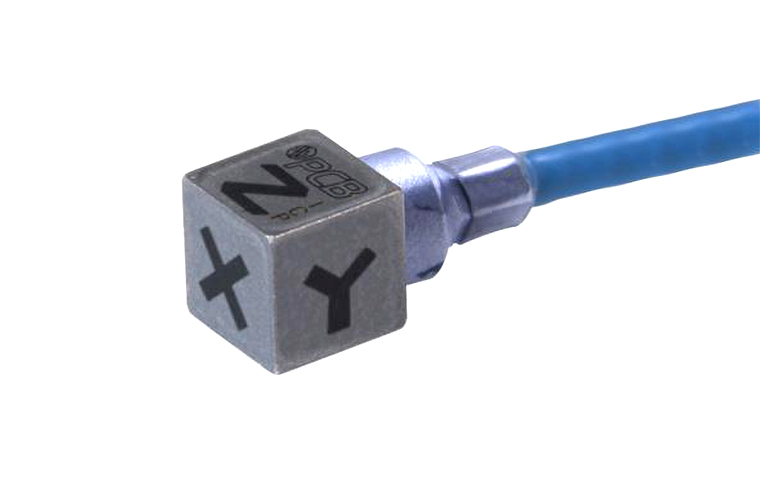

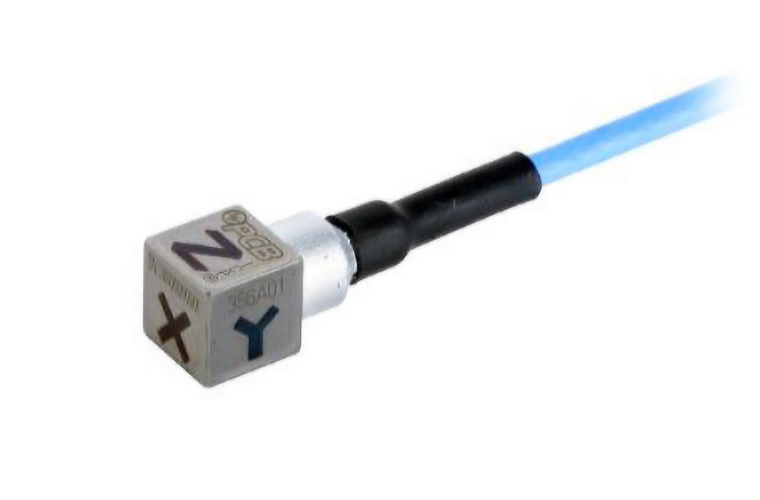

Triaxial accelerometers are designed

with three orthogonal sensing elements to enable simultaneous multi-axis measurements (x-, y-, and z-axis). Smaller, low mass accelerometers minimize mass loading effects and permit installation into confined areas.

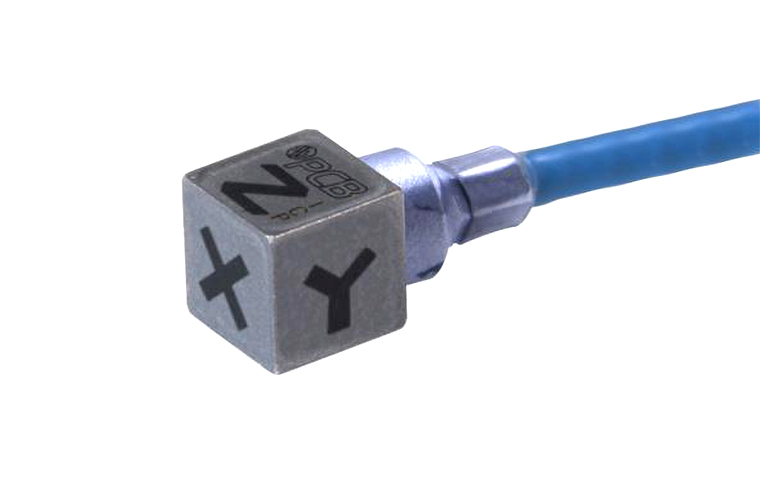

Triaxial accelerometers are designed

with three orthogonal sensing elements to enable simultaneous multi-axis measurements (x-, y-, and z-axis). Smaller, low mass accelerometers minimize mass loading effects and permit installation into confined areas.

| Amplitude Range (g) | Integral 5ft (1.5m) cable to 1/4-28 4-pin jack | 8-36 mini 4-pin jack connector | ||

|---|---|---|---|---|

| No breakout cable supplied. Use 010G, 034G, or 078G cable type to terminate to BNC | 5ft (1.5m) breakout cable terminating in (3) BNC plugs | No breakout cable supplied. Use 034K cable type to terminate to BNC | 5ft (1.5m) breakout cable terminating in (3) BNC plugs | |

| 500 | 356A03/NC | 356A03 | 356A09/NC | 356A09 |

| 1 000 | 356A01/NC, HT356B01/NC | 356A01, HT356B01 | 356A06/NC | 356A06 |

| 5 000 | 356A04/NC | 356A04 | ||

| 20 000 | 356A05/NC | 356A05 | ||

HT models operate in high-temperature environments (see specs for details)

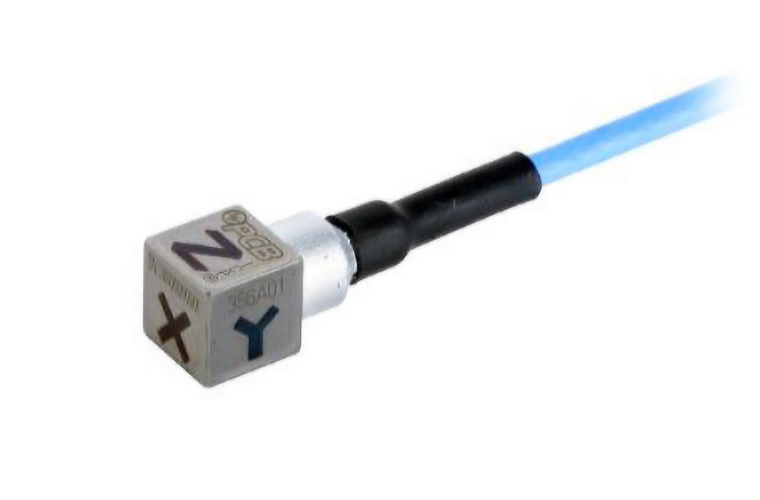

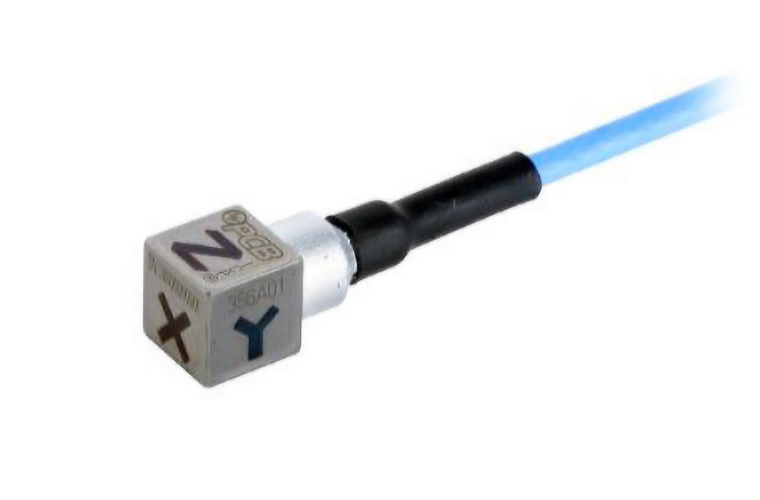

Lightweight ceramic shear design, titanium cased hermetically sealed accelerometers that minimize the effects of mass loading.

Key Specifications

Rental Includes

Key Specifications

Rental Includes

Similar to: Endevco 35C-2, Dytran 3133A4

Key Specifications

Rental Includes

Similar to: Endevco 35A, Dytran 3133A3

Key Specifications

Rental Includes

Key Specifications

Rental Includes

Similar to: Endevco 35A, Dytran 3133A3

Key Specifications

Rental Includes

Similar to: Dytran 3133A1

Key Specifications

Rental Includes

Users should be aware that the addition of any mass (such as an adhesive or a magnetic mounting base) to an accelerometer lowers the resonant frequency of the sensing system and may affect the accuracy and limits of the accelerometer's usable frequency range. However, adhesive mounting is sometimes the only available option to fasten an accelerometer to a test object.

When using an adhesive mounting technique, it is recommend to use a mounting base whenever possible to preserve the accelerometer's useful life. These adapters are normally first glued to the test surface, then the accelerometers are stud mounted to them. Most adhesive mounting bases available from PCB® are constructed of anodized aluminum and provide electrical isolation, eliminating potential noise pick-up and ground loop problems.

No matter what mounting technique is being used, the surface preparation is crucial for obtaining the best measurement results. A smooth and flat machined surface will achieve a higher degree of surface contact and thus the best high frequency transmissibility. When using the adhesive mount method, expect high frequency responses to be dampened in direct relationship to the mass of the accelerometer.

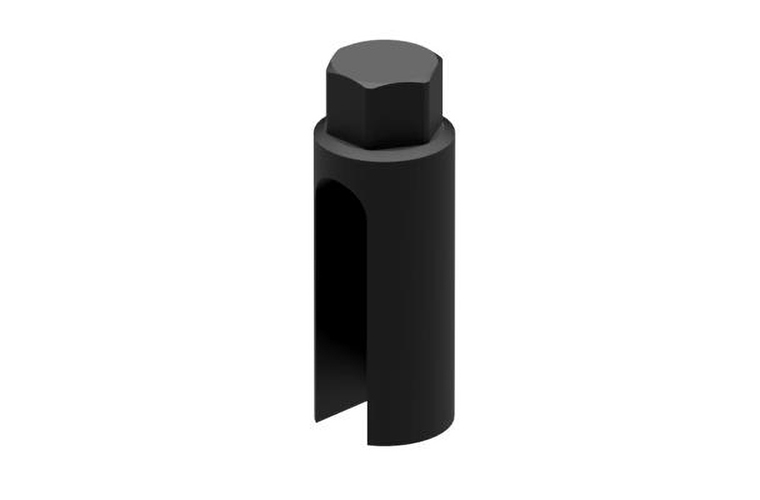

Avoid sensor damage by using tool and applying shear force, see video. One removal tool is supplied for each model of applicable sensor rented, contact us if additional removal tools are required.

Petro wax provides a simple mounting method for many applications meeting all of the following conditions:

One square is 1”x1”x0.25”

Quick Bond Gel. Cyanoacrylate-based mounting methods offer an ideal mounting method for lightweight accelerometers (under 20 grams). A fast room temperature cure time coupled with both wide useable frequency and temperature ranges makes this option very popular. Be sure to use a debonder such as acetone and wait a few minutes before removing the sensor.

Calibration data is provided electronically (on CD or USB memory stick) or as printed copies, depending on quantity rented and end-user preference.

The Modal Shop has internal calibration intervals set for most test products at 1 year. ANSI/ISO/IEC 17025:2000 makes clear that it is the responsibility of the end-user organization (in this case, the renter) to determine the appropriate calibration interval under the requirements of its own quality system. Per this, calibration certificates of rented equipment have "calibrated on" dates, but blank "calibration due" dates. Rentals ship with a customer specific expected return date in mind - if equipment is expected out for 5 months, the last calibration date will be within the past 7 months. Calibration to additional standards (e.g. Z540 or specific FAA requirements) are possible, but there may be an additional charge.

The Modal Shop's Scope of Accreditation can be found here. An example of a calibration certificate can be found here. Please contact us with questions or if a different calibration will be needed for your rental sensors.