Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

To help explain the Resonant Acoustic Method (NDT-RAM), let’s consider how a person can determine between a good bell ![]() and a cracked bell

and a cracked bell ![]() .

.

Impact | Measure | Process | Quantify | |||

| → |   | → |  | → |   |

| The impact “rings” the bell and produces sound. | Ears pick up the sound and transform it to an electrical signal. | The brain processes the signal into tones or notes, also known as frequencies. | A comparison is made to bells heard before to determine “pass” or “fail.” |

Impact | Measure | Process | Quantify | |||

| → |   | → |  | → |   |

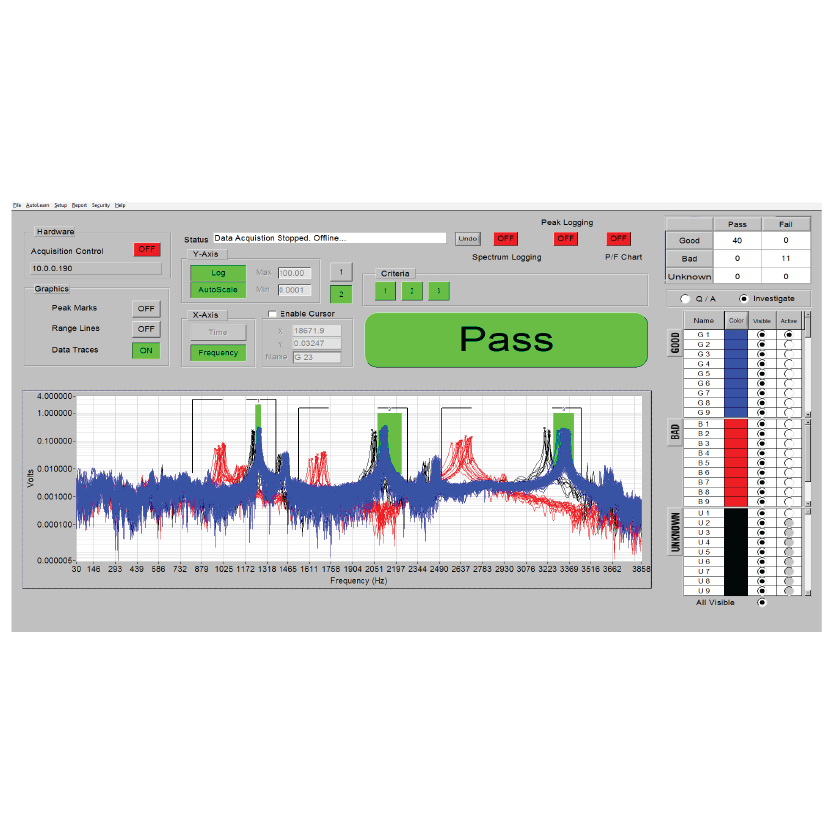

| An industrial impactor taps each part with a measured and repeatable force, producing sound. | A microphone is used to transform the parts' response into electrical signals for analysis. | The smart digital controller uses a Fast Fourier Transform (FFT) method to determine frequency characteristics. | NDT-RAM software compares the results to criteria limits and accepts or rejects the part accordingly. |

Impact the Part

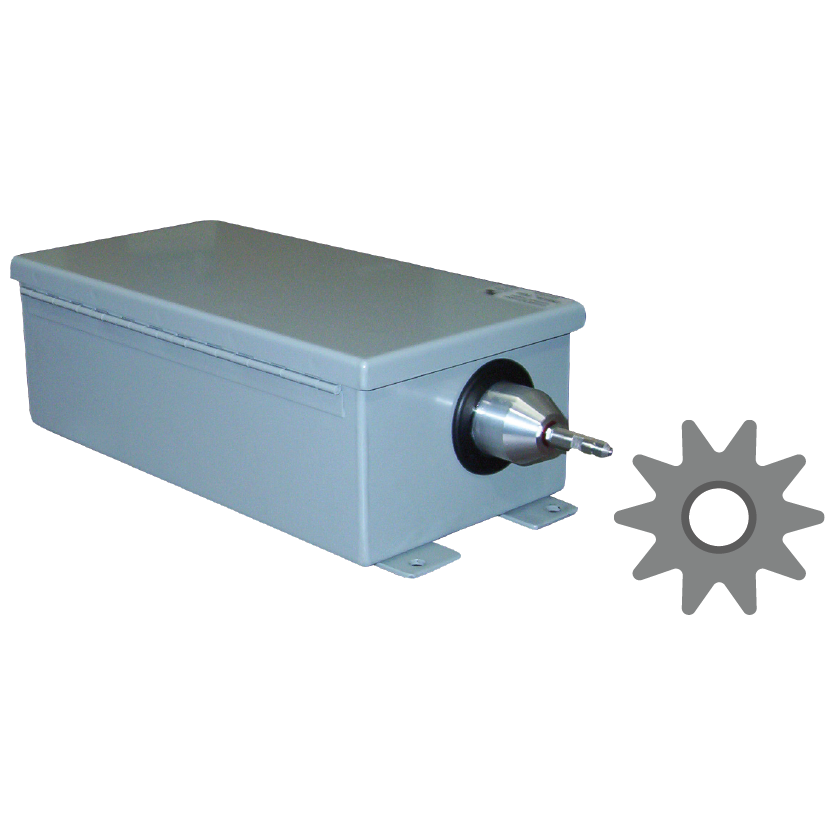

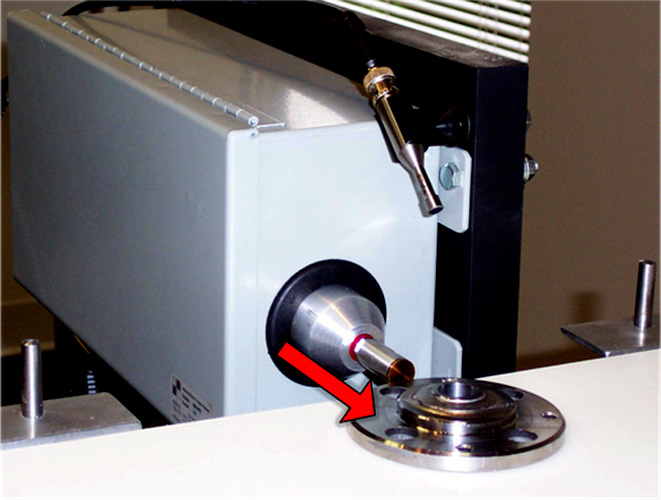

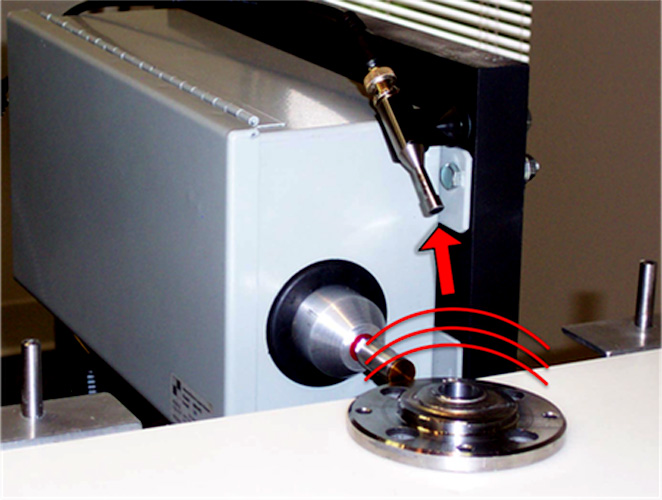

Impact the PartThe part can either be impacted with a manual hammer or an industrial electric hammer. It is important to excite the part with a proper, repeatable force. This will improve the repeatability and reliability of the test.

A microphone is used to provide accurate acoustic measurement of the component's resonant frequency and amplitude values. The NDT microphone provides a perfect fit of price, accuracy and dependability.

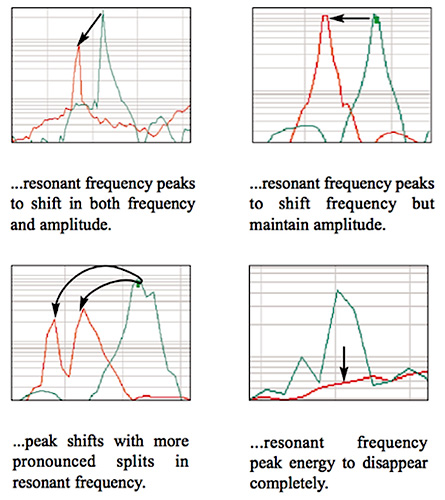

Changes in mass, stiffness and damping due to certain defects can cause...

The family of NDT-RAM systems range from a portable manual system ideal for parts investigation and troubleshooting, to a semi-automated system for easy integration into your existing process, to a fully automated conveyor-based or drop test fixture system as a turn-key solution for 100% parts inspection.