Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

Measuring dynamic forces with piezoelectric quartz sensors permits accurate capture of fast, transient forces associated with manufacturing processes and product testing. Unlike strain gage sensors that are suitable for slow changing or static loads, quartz dynamic force sensors possess the endurance to survive, and the response necessary to quickly and accurately follow fast-rising, short-duration crimping, stamping, punching, and impact events.

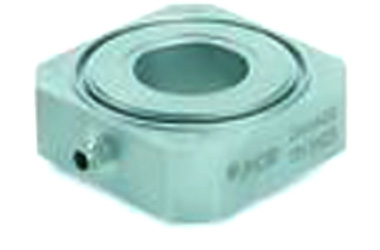

General purpose quartz force sensors measure dynamic tension and compression used in impact, drop, and material testing. They are also frequently used in dynamic shaker testing. Setup is easy - the force sensor must be mounted to the object under test and connected to the shaker via a stinger.

Series 208 units are stainless steel, 22.7 gram mass and have a side 10-32 coaxial cable jack. All units have a temperature range of -65 to +250°F (-54 to +121°C) and include an impact cap (084A03) and a 10-32 mounting stud (081B05). A 003C style cable should be used to connect to the BNC. Metric mounting studs (M081A62) are available upon request.

| Model | Meas. Range (Compress) lb (N) | Meas. Range (Tension) lb (N) | Sensitivity mV/g (mV/N) | Broadband Resolution lb-RMS (N-RMS) | Lower Freq. Resp. (-5%) | Max Static Force (Compress) lb (kN) | Max Static Force (Tension) lb (kN) |

|---|---|---|---|---|---|---|---|

| 208C01 | 10 | 10 | 500 | 0.0001 | 0.01 | 60 | 60 |

| 208C02 | 100 | 100 | 50 | 0.001 | 0.001 | 600 | 500 |

| 208C03 | 500 | 500 | 10 | 0.005 | 0.0003 | 3000 | 500 |

| 208C04 | 1000 | 500 | 5 | 0.01 | 0.0003 | 6000 | 500 |

| 208C05 | 5000 | 500 | 1 | 0.05 | 0.0003 | 8000 | 500 |

Rental Includes:

Rental Includes:

Rental Includes:

Rental Includes:

Rental Includes:

A mechanical impedance head includes both a quartz force sensor to measure dynamic tension and compression as well as an accelerometer. They are often used to obtain driving point measurements in modal and structural analysis. Mount the unit to the object under test and connect to the shaker via a stinger.

Series 288 units are stainless steel, 19.2 gram mass and have two side 10-32 coaxial cable jacks. Units have a temperature range of 0 to +200°F (-18 to +95°C) and include an adhesive mounting base (080A) and two 10-32 mounting studs (081B05). 003C style cables are also available, and connect to analysis equipment via BNC. Metric mounting studs (M081B05, 10-32 to M6 X 0.75) are available upon request.

TEDS version available

Rental Includes:

Full Force Limited Vibration Test systems are available for rental as well as the the individual transducers.

Rental Includes:

Rental Includes:

Rental Includes:

High resolution, high sensitivity and fast response make the Model 740B02 ideal for the measurement of dynamic strain. The sensor integrates a proprietary quartz sensing element and built-in microelectronic circuitry within a low-profile titanium housing. The strain sensor provides a resolution of 0.0006µe over a 0.5 to 100,000 Hz bandwidth. It is compatible with PCB's ICP® sensor signal conditioners and is capable of driving long cables. Typical applications include: active vibration control, noise-path analysis, and modal testing, as well as use on aircraft and marine hulls, composite materials, "smart structures," and vibrating machinery.

Rental Includes: