Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

An automotive parts supplier of air bag propellant diffusers was experiencing cracks during the drawing process. Customer complaints eventually caused manufacturing to require costly and time-consuming 100% visual inspection.

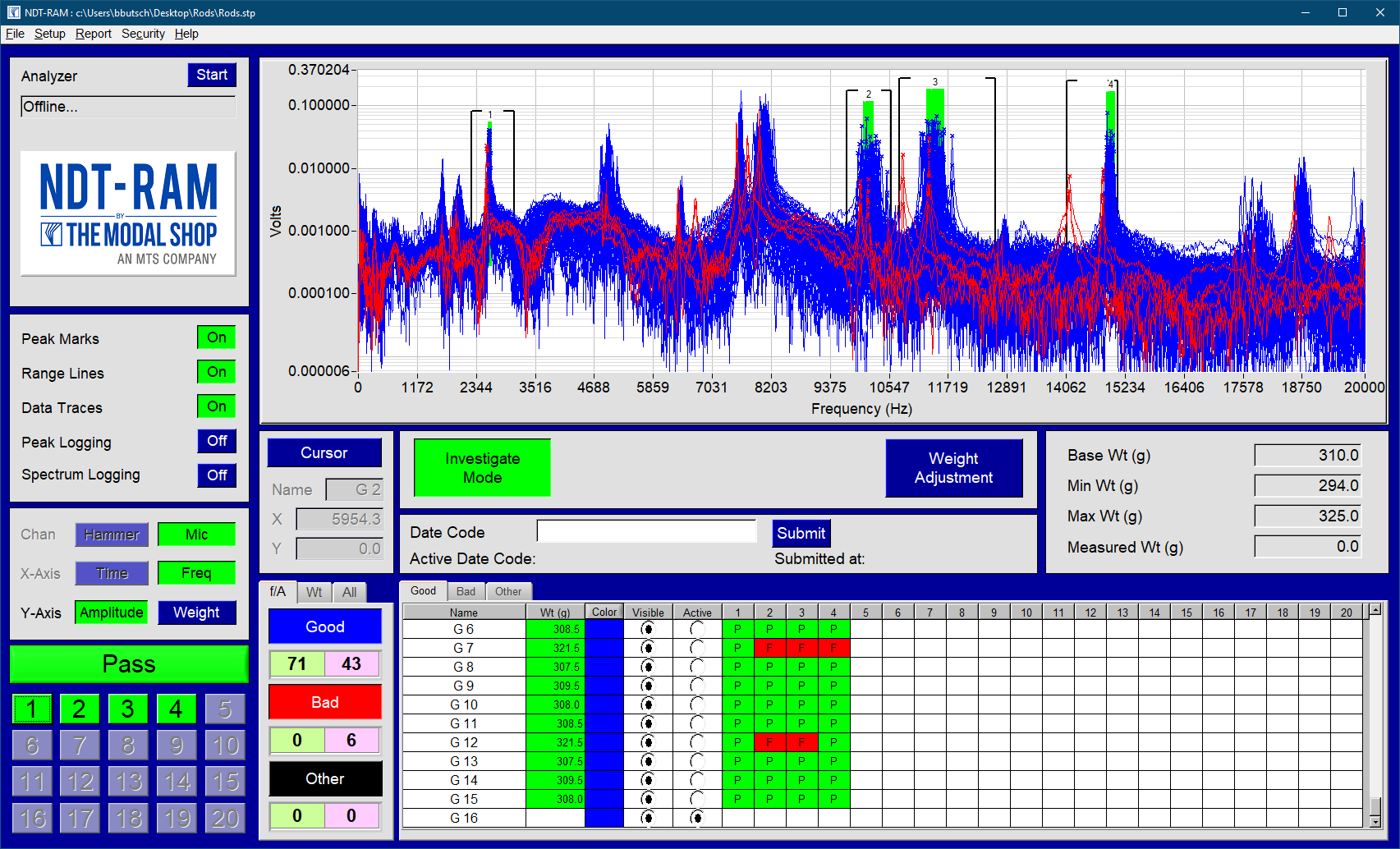

To keep up with the very high throughput rate of stamping operations, the extremely fast NDT-RAM resonant inspection technique was implemented, detecting frequency shifts by "ringing" flawed parts. The system objectively determines whole part integrity automatically at approximately 1 to 3 seconds per part, typical* using an industrial conveyor and a synchronized electric impactor to ring the parts. The quality analysis and control system detects frequency shifts with a measurement microphone.

100% objective, whole part quality inspection was achieved and kept pace with the stamping operation. The subjective errors and costs of visual inspection were eliminated AND customer confidence and satisfaction increased. The inspection system paid for itself in less than 14 months.