Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

Assuring the structural integrity of complex Metal Injection Molded (MIM) parts is a critical step in quality management systems, especially in medical device applications. Cracks, missing features and porosity can be difficult or impossible to detect via visual inspection. Traditional scanning methods of nondestructive testing can be cost prohibitive.

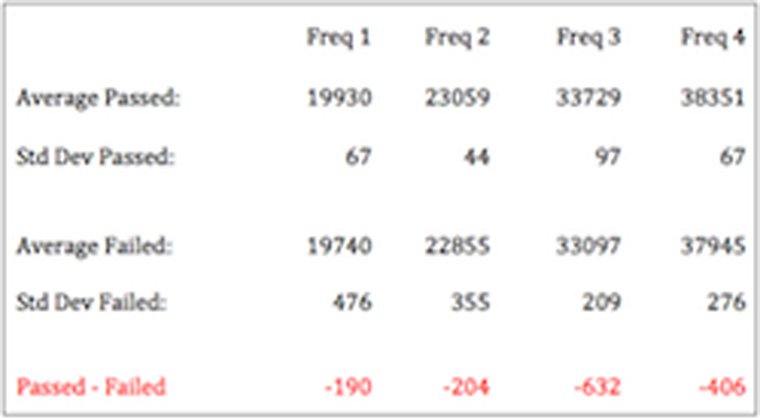

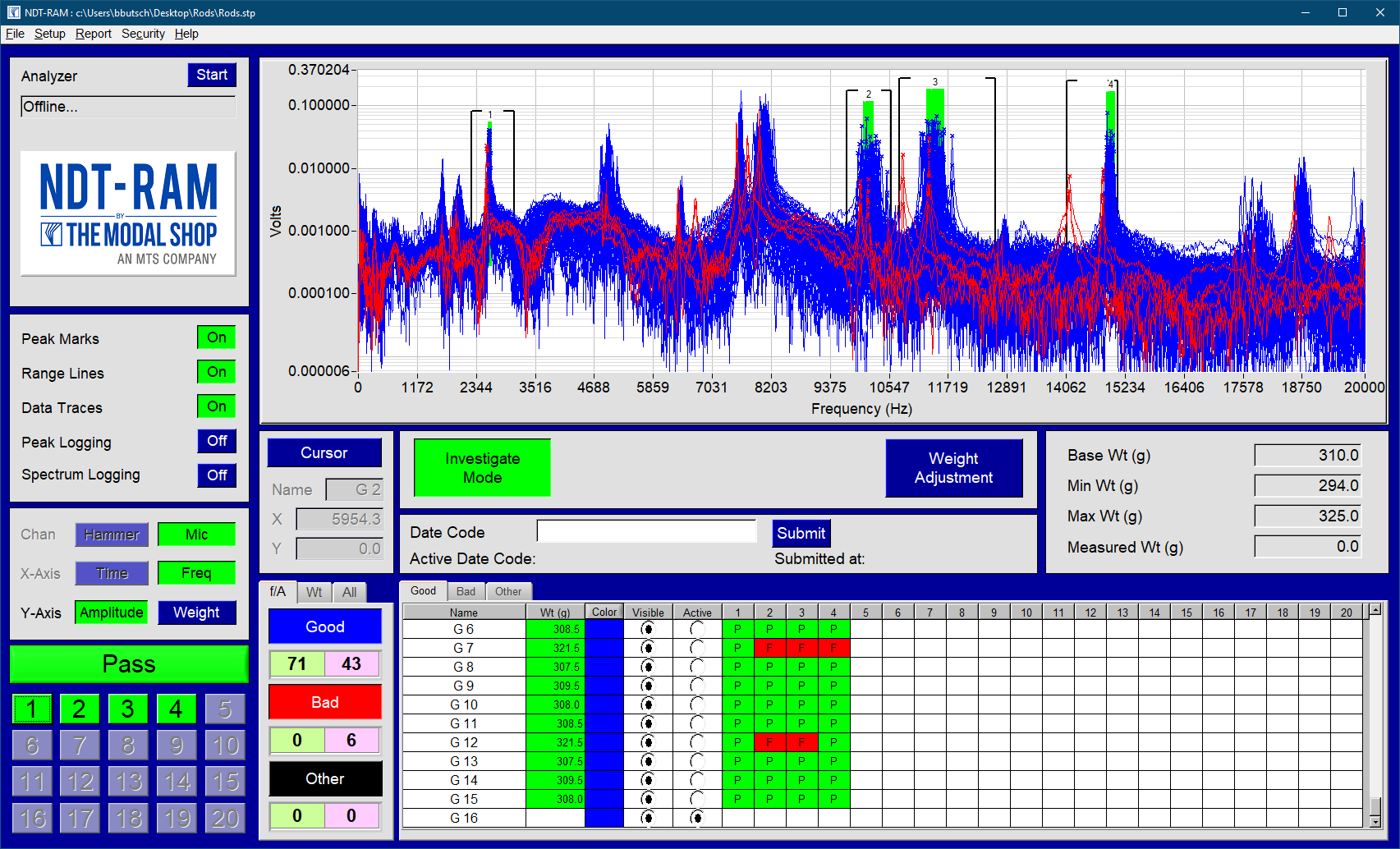

Non-Destructive Testing Resonant Acoustic Method (NDT-RAM™) provides an extremely fast, whole body indication of structural integrity on 100% of parts produced. Resonant frequency shifts caused by flaws such as cracks, missing features or missed operations are readily detected. In addition, the system acts as a process monitor – if the resonant frequencies change beyond the norm, the manufacturing process can be halted, investigated and root cause determined sooner, saving time, scrap and liability.

By correlating the resonant frequency shifts to gauging and x-ray results, NDT-RAM can easily, objectively and reliably detect flawed parts before the customer does. Performing inspection on 100% of MIM parts produced reduces liability, raises customer satisfaction, increases confidence in zero defect shipments and protects your reputation.