Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

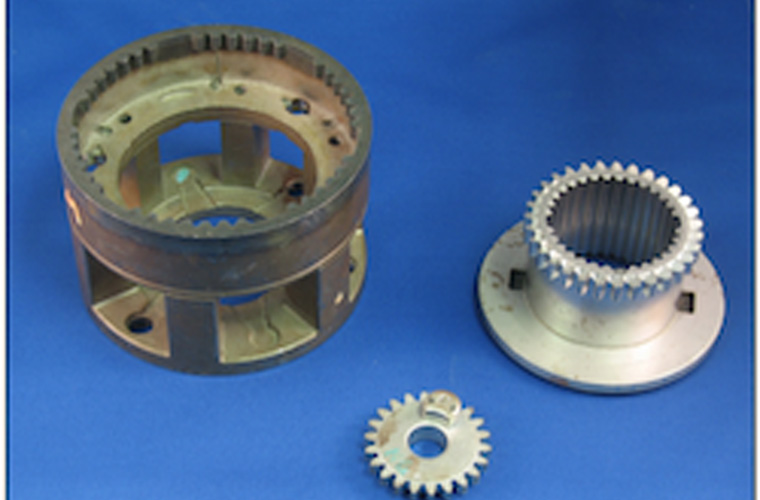

Testing the structural integrity of complex powder metal parts joined via sinter braze is a critical step in ensuring the part will perform as designed. Incomplete braze infiltration, improper braze alloy, damaged or even missing braze pellets can be difficult or impossible to detect via visual inspection or traditional methods of nondestructive testing.

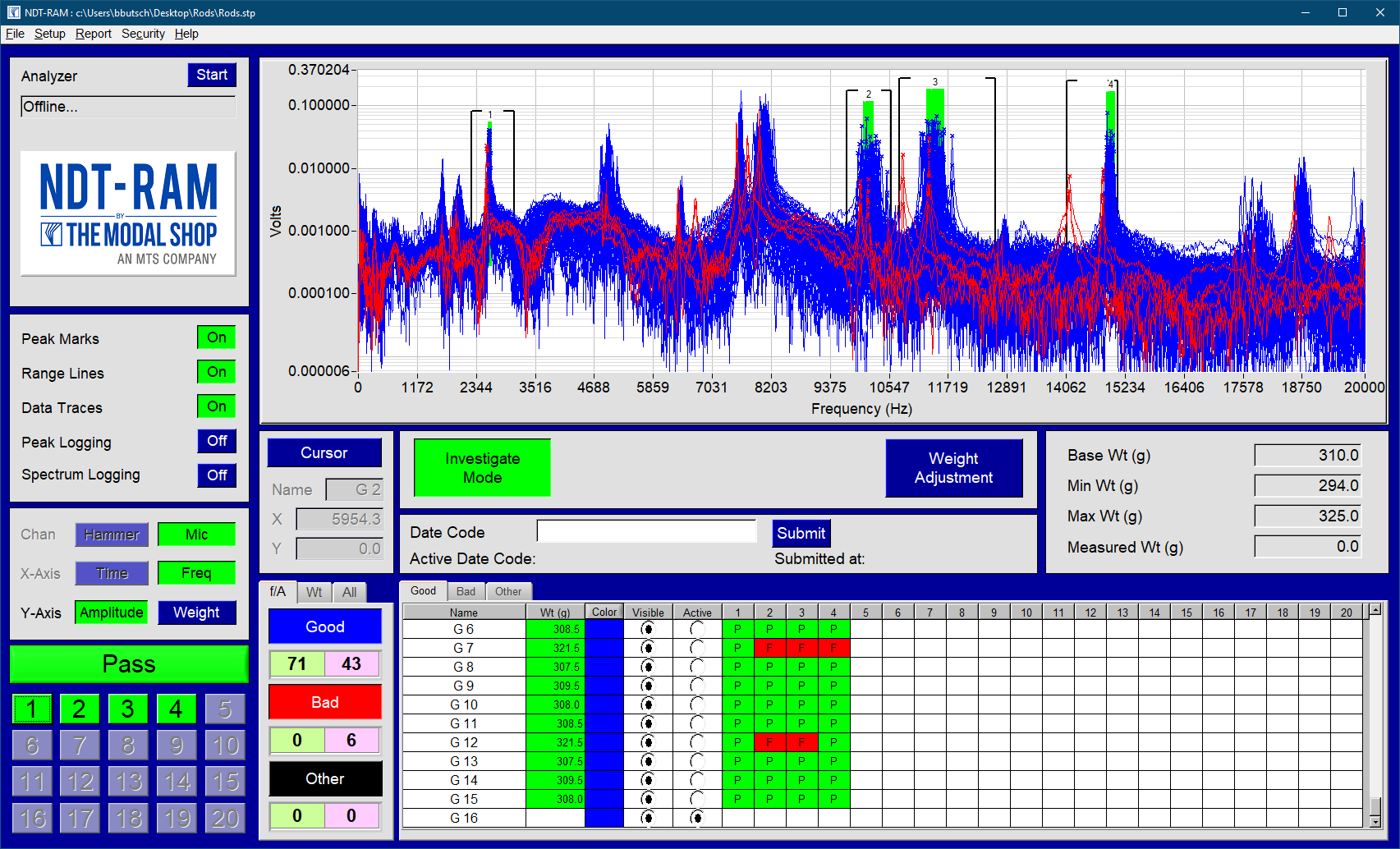

Resonant Acoustic Method NDT (NDT-RAM) provides an extremely fast, whole body indication of braze integrity on 100% of parts produced. Resonant frequency shifts caused by the structural weakness of poor sinter brazing are readily detected. In addition, the system acts as a process monitor if the failure rate increases beyond the norm, the process can be halted, investigated and root cause determined sooner, saving time and money on scrapped parts.

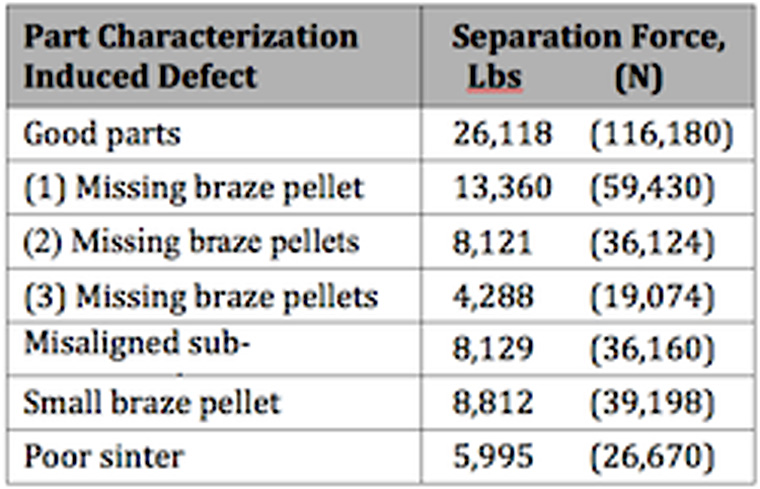

By comparing the resonant frequency shifts to visual and destructive separation pull force evaluations, NDT-RAM can easily, objectively and reliably detect poor sinter brazed joints. The capability of automating NDT-RAM makes it superior to subjective visual or inefficient separation-force testing.