Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

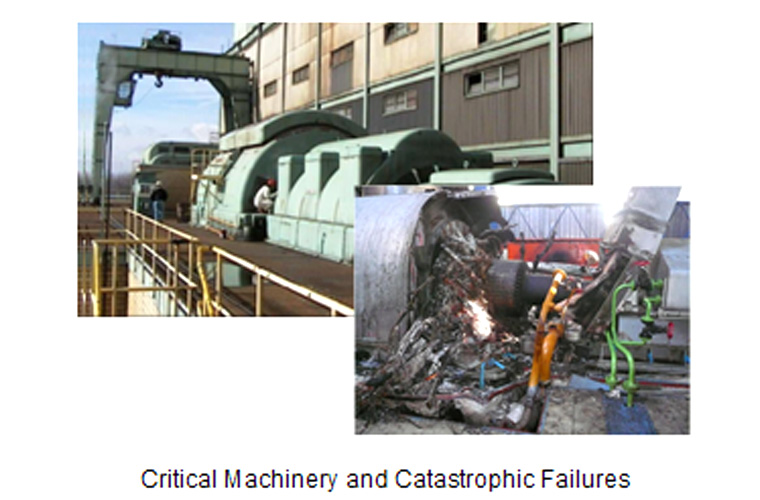

Protecting process quality and critical plant machinery from damage or destruction is a constant concern in the industrial environment. Quality affects customer satisfaction and yield. Maintenance and shutdown related issues cost companies both time and money. Validating the health of an installed monitoring system is key to ensuring overall success. Vibration sensors, cabling and data acquisition systems must be operating accurately to ensure facility and machinery safety.

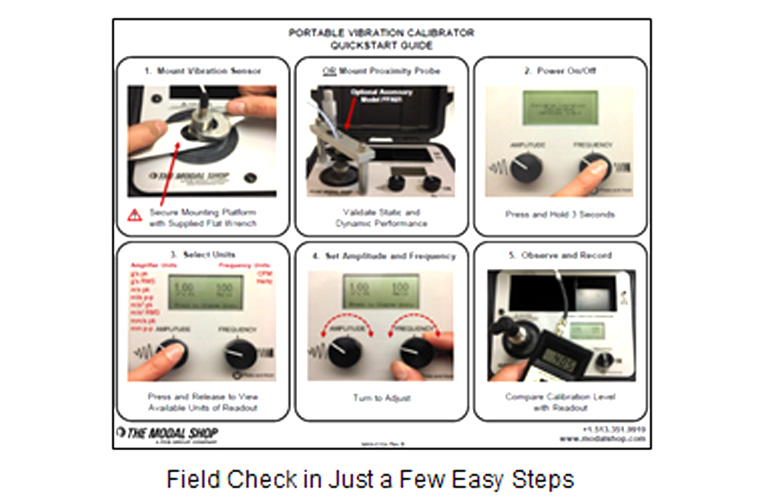

The 9100D Portable Vibration Calibrator performs on-site calibrations of accelerometers, velocity sensors and proximity probes. Designed to withstand the harsh conditions of the industrial environment, the 9100D can be taken directly to the location of installed sensors, eliminating downtime and making regular calibration a viable option. During calibration, the unit can validate the entire measurement channel from sensor through signal conditioning, acquisition system and display console, providing the peace of mind that the entire system is accurate and functioning. Vibration monitoring alert and alarm trip points can also be tested to confirm function and accuracy.

The 9100D solves on-site vibration calibration needs in one self-contained, battery powered unit. It generates known vibration excitation levels and offers standardized, traceable results for each calibration. Rugged hardware, an easy to use system interface, extensive battery life, and precision electronics make the 9100D an ideal tool for field calibrations and validation of the measurement channel.