Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

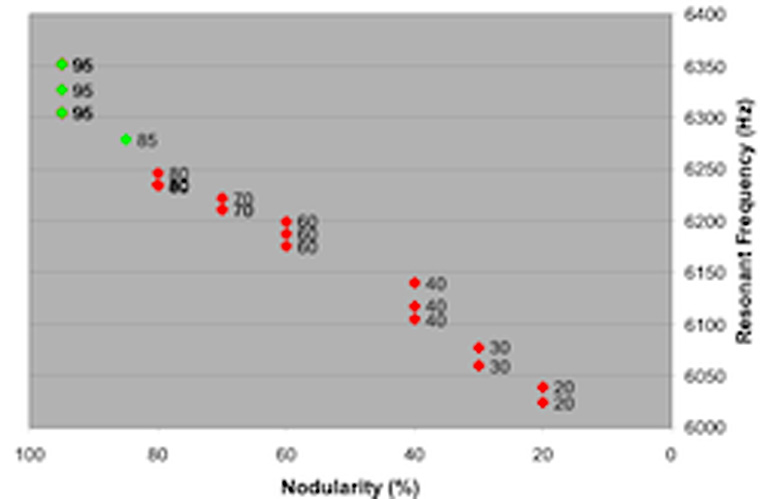

The measurement of nodularity in ductile iron parts is time consuming and subjective by means of both visual sectioning and UT immersion. Often parts are repositioned on UT probes to gain a forced pass and additional steps and costs are needed to prevent rust and oxidation after immersion.

Non-Destructive Testing Resonant Acoustic Method (NDT-RAM) provides an extremely fast, whole body indication without immersion or part preparation. By impacting parts and windowing critical resonant frequencies, the system automatically screens for parts exhibiting nodularity below your customer's critical specification.

Computerized testing with NDT-RAM and economical automation ensures a simple, reliable, affordable means to screen for nodularity without the compounding troubles caused by immersion. Additionally, the resonant method provides a whole body indication of nodularity rather than merely a local spot check.