|

Tip of the Month: Calibration with Fixtures

|

Mechanical fixtures are often required for mounting accelerometers for calibration. Use fixtures that are designed to be very low mass and high stiffness, recognizing the potential impact on the mounted resonant frequency. Consider an accelerometer with a 5-40 integral stud mount. A slight but measurable difference will be seen at the higher frequencies (around 10 kHz) during calibration when comparing data acquired with the accelerometer directly mounted to a piggyback reference to data acquired against a reference with the typical ¼-28 mount and an adapter. This can be an issue because manufacturers may calibrate the accelerometers with no adapter (best case scenario) while commercial systems require a variety of adapters to maintain maximum flexibility in the field.

|

| Quick Links |

ISO TC 108 - Mechanical vibration, shock and condition monitoring

ISO TC 108/SC 3 - Use and calibration of vibration and shock measuring instruments

SAVIAC

|

| Previous Newsletters |

Lab Lessons Learned, Series 1; Principles of Dynamic Calibration

|

| Select Newsletter Articles by Topic | |

|

|

|

Lab Lessons Learned from Student Testing,

Part 3 (By D.E. Adams, J. Jaques, M. Strus, A. Vyas and R.W. Bono)

| |

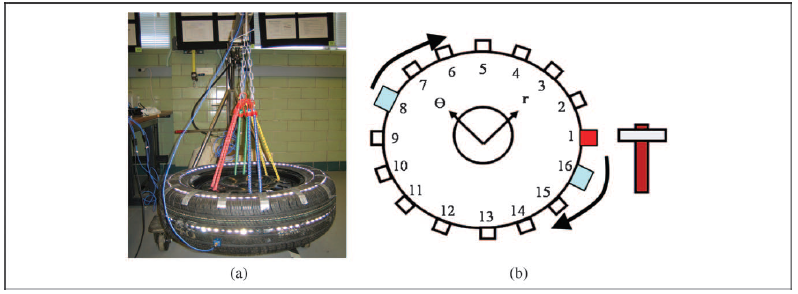

In last month's lesson, students analyzed road conditions with spectral analysis using an automotive suspension system as a mobile operating data acquisition system. This month, the students tackle tires. Their project studied the differences in tire response due to excitation across the tread width using modal impact testing and transmissibility analysis.

The student objectives were: first, to identify the transverse, radial and tangential mode shapes and natural frequencies of the tire and, secondly, to determine if the forced response changed appreciably when the tread was excited by the road on the inner, center or outer tread segments.

Click to read more

http://www.modalshop.com/calibration/.asp?ID=782

|

New Videos: How to Mount and Remove Sensors

|

If you have ever had questions concerning the proper way to mount or remove sensors for calibration, click the links below to view videos from our calibration tutorials with instructions on:

http://www.modalshop.com/calibration.asp?ID=777

|

|

Blast From the Past: Modal Array Accelerometer...What Makes a Good One?

| |

For those who may be new to our newsletter, we wanted to highlight an article from a previous Sensor & Calibration Tips: "Modal Array Accelerometer...What Makes a Good One?" For those who may be new to our newsletter, we wanted to highlight an article from a previous Sensor & Calibration Tips: "Modal Array Accelerometer...What Makes a Good One?"

There are literally thousands of different models of accelerometers available. This is due to each measurement application having slightly different goals and constraints, as well as different weightings as to which sensor specifications can be compromised. There are frequency ranges, amplitude g ranges, resolutions, packaging/connector configurations, weight, environmental considerations, etc.

With all the combinations and permutations, how is a user to wade through the volumes of models and feel confident in making a technically and economically sound choice? The short answer is application assistance. Be sure your chosen vendor provides knowledgeable, professional support people who can promptly assist with your phone call, email or request for a visit.

http://www.modalshop.com/calibration.asp?ID=209

|

| |

Thanks for joining us for another issue of Sensor & Calibration Tips. As always, please, speak up and let us know what you like. We appreciate all feedback: positive, critical or otherwise. Take care!

Sincerely,

|

Michael J. Lally A PCB Group Company

| |