Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

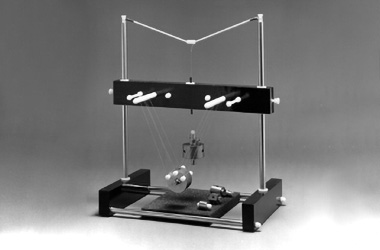

The Impact Hammer Calibration System allows users to quickly and easily calibrate their instrumented impact hammers and account for tip inertia or extender mass. The system

is available as Option 9155D-961 for use with a Precision Sensor Calibration Workstation Model 9155D. It is also available as a standalone solution Model 9961C.

The Impact Hammer Calibration System allows users to quickly and easily calibrate their instrumented impact hammers and account for tip inertia or extender mass. The system

is available as Option 9155D-961 for use with a Precision Sensor Calibration Workstation Model 9155D. It is also available as a standalone solution Model 9961C.

Impact hammer calibrations are performed by impacting a pendulous mass instrumented with a calibration accelerometer. Using Newton’s second law (F = ma), the measured acceleration is multiplied by the known mass to calculate the impact force. The

software supports calibration of instrumented hammers with up to eight different tips, both with and without an extender mass. This economical option uses the existing high-quality data acquisition system in the base Model 9155D Precision Sensor Calibration

Workstation to quickly and easily perform hammer calibrations and report the results on an easy-to-read, Microsoft Excel® based calibration certificate. Printed certificates fulfill the format requirements set forth by ISO 17025 for calibration

certificates.

| 9155D-961 Option | |

|---|---|

| Impact Range - lbf (kN) | 0 - 1 000 (0 - 4.45) |

| Measurement Uncertainty at Reference Frequency | 2.5% |

| Measurement Technique | Gravimetric Comparison |

| Measurements Supported | Sensitivity |

| Actuator Model | 9961C |