Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

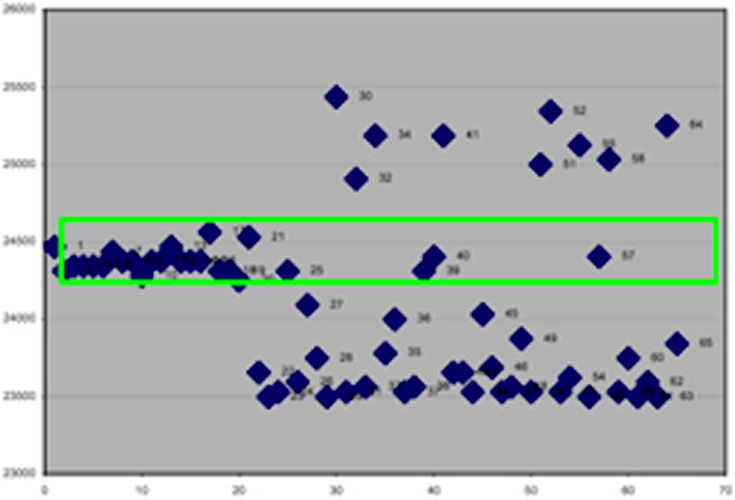

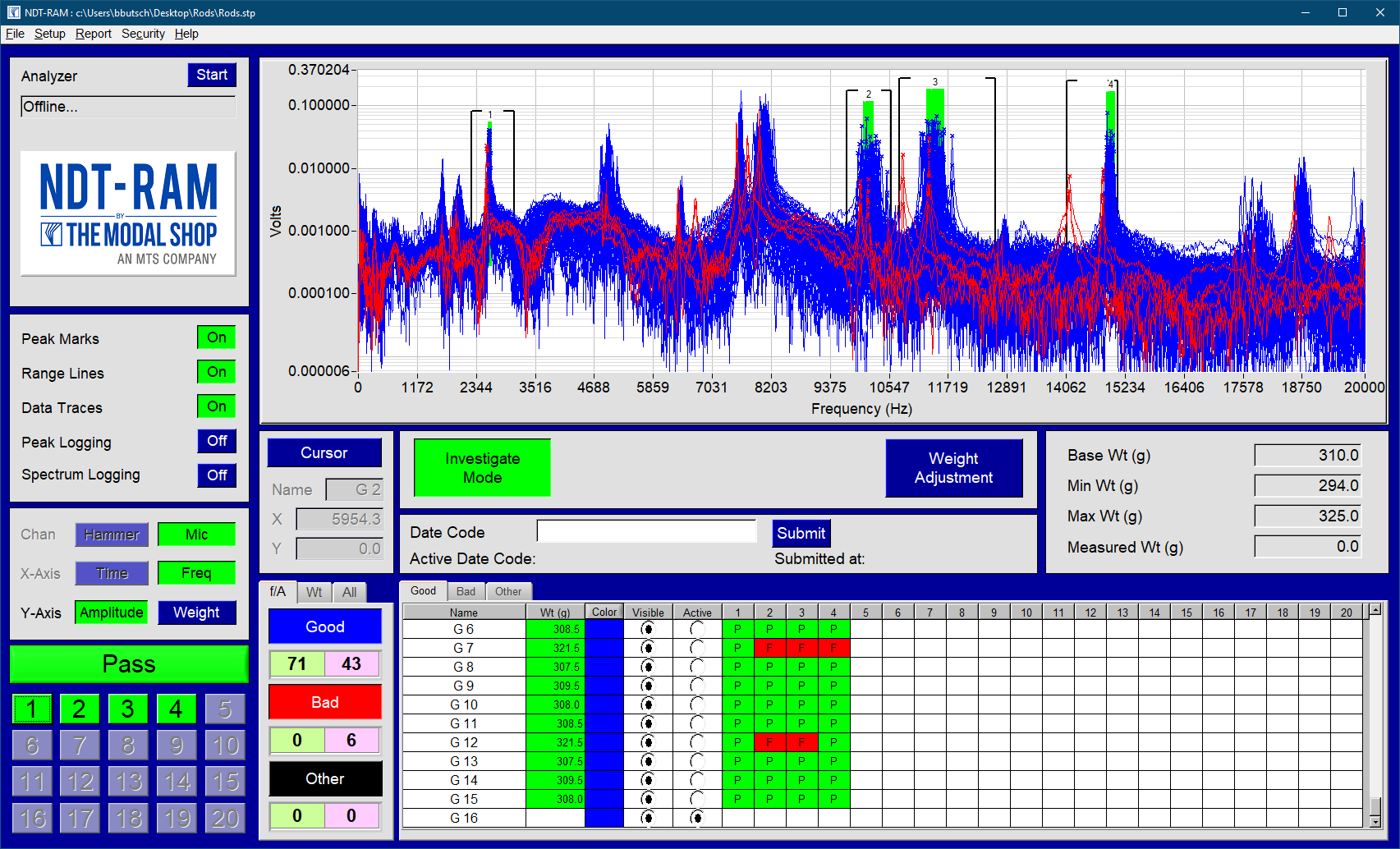

A manufacturer of a disk shaped hub was experiencing crack formations in parts due to a variance in press settings. Redundant 100% post sintering visual inspection was not only time consuming and expensive, but was also unreliable as it failed to catch many of the cracked parts.

The NDT-RAM (Non-Destructive Testing Resonant Acoustic Method) resonant inspection technique detected cracks of two levels of severity. The on-line quality inspection system required no part preparation and was automated with a high throughput conveyor. 100% quality screening was achieved at a rate of about a part a second.

In addition to saving the significant labor time and cost involved in visual inspection, the manufacturer has objective 100% quality inspection and an on-going dynamic measurement of whole part integrity. By consistently monitoring the dynamic shifts, process improvements were identified and implemented to reduce scrap and enhance efficiency for increased bottom line profits.