Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

An automotive parts supplier of brake calipers was experiencing cracks in the finished parts. Heavy pressure from the supplier's customer drove the parts supplier to batch inspecting via magnetic particle technique and redundant 200% visual inspection.

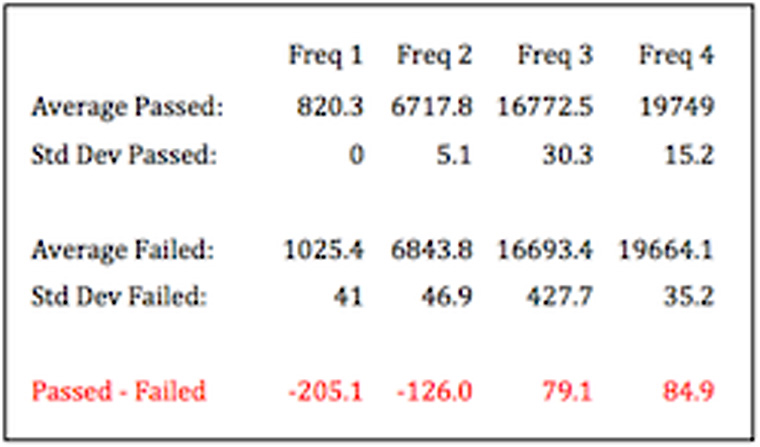

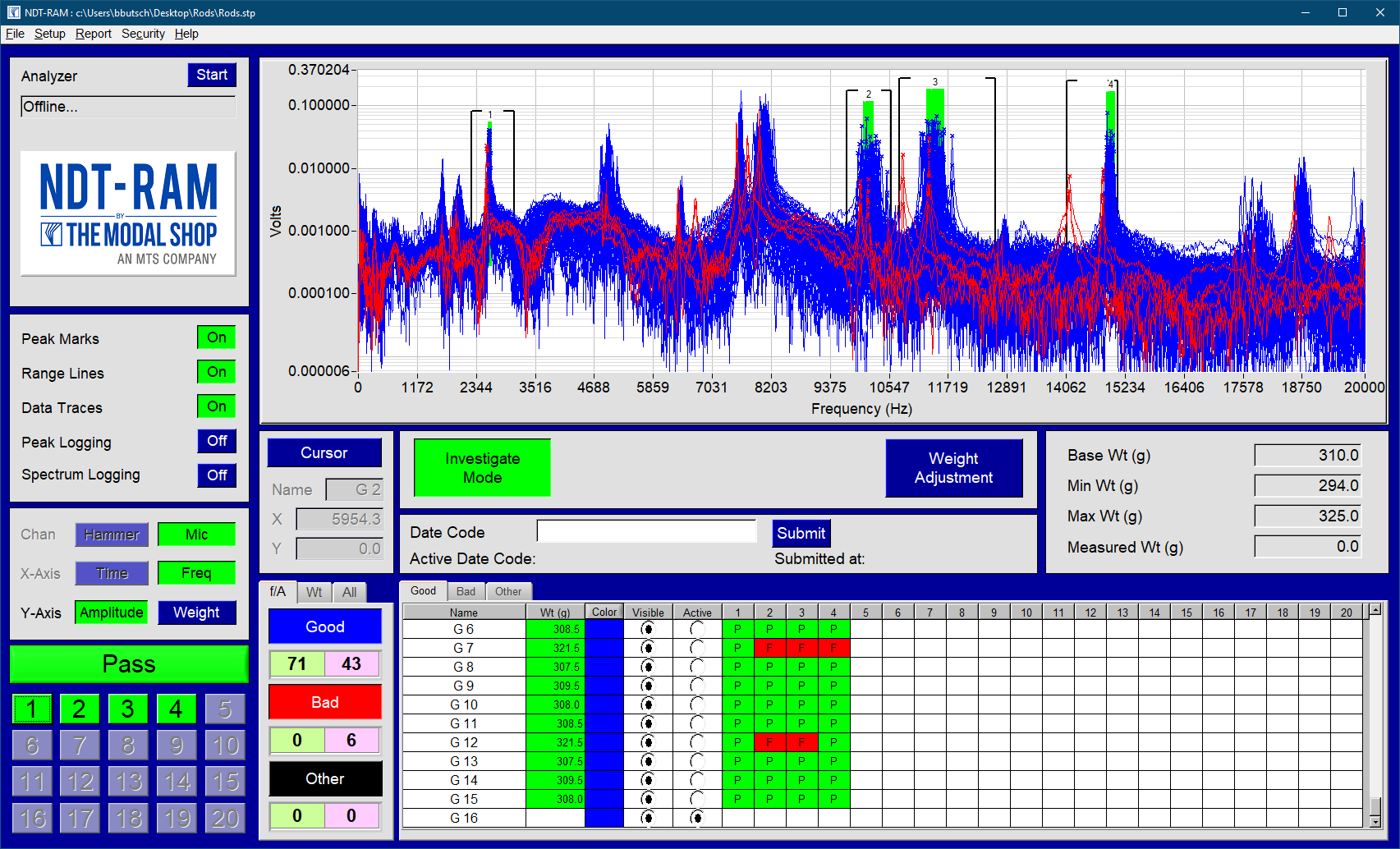

A pass/fail criteria template was developed from trial parts then implemented in an on-line quality inspection system. Cracks in flawed parts were easily detected at high throughput rates using the NDT-RAM Resonant Inspection technique. The system automates objective whole part inspection at approximately 1 to 3 seconds per part using an industrial conveyor and synchronized industrial impactor.

100% part quality inspection via NDT-RAM assured objective and reliable inspection. Reliable design provided fast and reliable 24/7/365 operation with high throughput. As a result, both magnetic particle and visual inspection were eliminated on this part, saving time and money