Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

Automated manufacturing has allowed for unprecedented reductions in part costs. When all is working well, hundreds of thousands or millions of quality parts roll off the lines. Unfortunately, when a quality problem arises, hundreds or thousands of bad parts can be produced before flaws are detected and solved.

Dynamic gauging and nondestructive test for automated production lines ensure quality production 100% of the time. Installed in major automotive manufacturers and many tier one suppliers as "online sentries," these systems monitor the production process and part integrity to ensure quality manufacturing, identifying part flaws (hardened material, upstream rougher tolerance, powdered metal defects, etc.) and manufacturing anomalies (loose clamp, dull/broken tools, loose gibs, improper tool setup, etc.) which can alert operators and save millions of dollars in both rework, scrap parts and warranty claims/recalls.

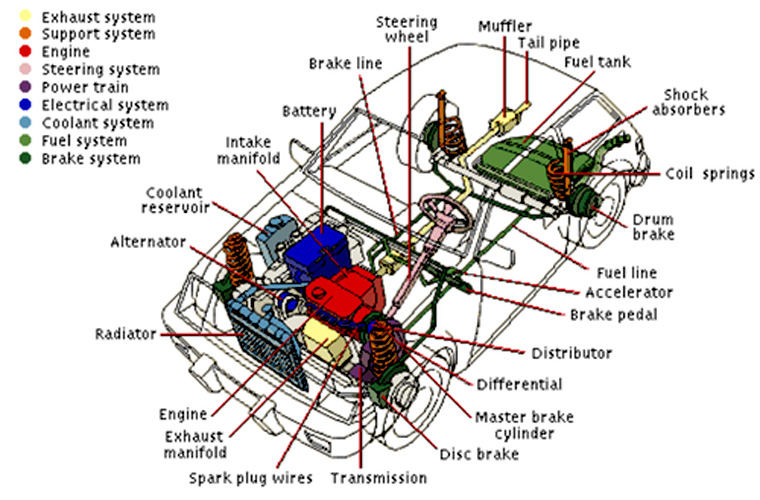

Resonant Inspection via Non-Destructive Test Resonant Acoustic Method (NDT-RAM™) is designed to help you supply 100% fully inspected component parts. Capable of testing parts such as powder metal, cast, ductile iron, forged or stamped metal, and more, NDT-RAM offers you assurance in the integrity of your product and performance. Below find a list of some typical automotive parts tested using NDT-RAM. Learn more about NDT-RAM.

Exhaust Subsystem

| Steering System

| Safety Subsystem

|

Engine Subsystem

| Transmission Subsystem

| Brake Subsystem

|

In powder metal (PM), cast, ductile iron, forged or stamped parts, NDT-RAM detects variances such as cracks, voids, nodularity, missing features and missed manufacturing processes. The entire procedure occurs as fast as one to three seconds per part, allowing for efficient and cost-effective quality assurance. Your performance is guarded, your liability is limited and your reputation in the industry grows. As a contributor to state-of-the-art innovative quality inspection, The Modal Shop is an active member of the Metal Powder Industries Federation (MPIF), American Society for Nondestructive Testing (ASNT), and ASTM International.

All of the NDT-RAM systems are ideal for 100% inspection requirements of manufacturers or users of powder metal, metal injection molded (MIM), castings (including ductile iron), forgings or stampings that have significant inspection costs (either material or labor costs), produce or use safety-critical parts, have substantial scrap costs due to false rejects or simply want to improve their part quality.

* Part throughput rate dependent upon part size, belt size, data acquisition setup parameters, and other part handling requirements