Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

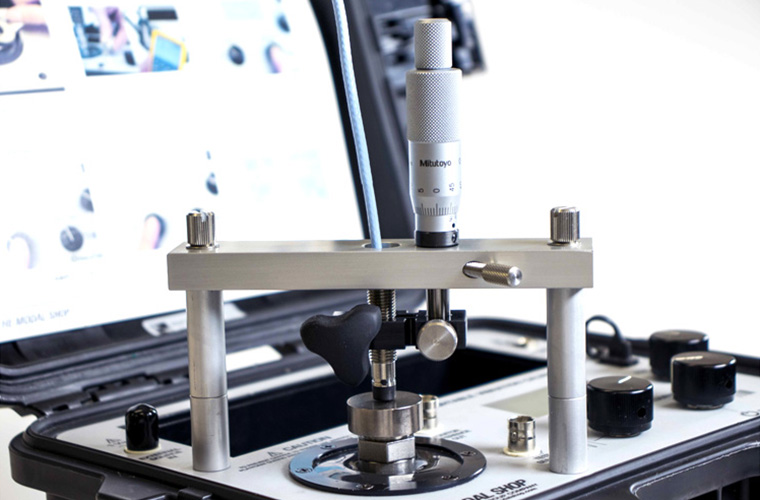

Non-contact proximity probes – or eddy current probes – are used to monitor vibration on the world’s most critical rotating equipment such as turbines and compressors. These transducers are reliable and accurate but are more complex to install correctly than other vibration instrumentation. Incorrect impedance leads to false alarms or catastrophic failures. Gap voltage alone is incapable of detecting such faults. Portable Vibration Calibrators identify incorrect probe sensitivity which leads to improper alarm operation. Calibrators test proximity probes dynamically, mechanically simulating the shaft motion that the probes will measure while in use. Pass your audit by quickly and easily creating probe calibration reports via a calibrator’s memory as opposed to manually charting voltage output vs. gap.

Non-contact proximity probes – or eddy current probes – are used to monitor vibration on the world’s most critical rotating equipment such as turbines and compressors. These transducers are reliable and accurate but are more complex to install correctly than other vibration instrumentation. Incorrect impedance leads to false alarms or catastrophic failures. Gap voltage alone is incapable of detecting such faults. Portable Vibration Calibrators identify incorrect probe sensitivity which leads to improper alarm operation. Calibrators test proximity probes dynamically, mechanically simulating the shaft motion that the probes will measure while in use. Pass your audit by quickly and easily creating probe calibration reports via a calibrator’s memory as opposed to manually charting voltage output vs. gap.

Loop Check Proximity Probes without Removing from Housing |

Proximity Probe Cabling Errors |

Mounting Proximity Probes for Testing and Calibration

|

Create Proximity Probe Calibration Certificates

|

Wobulator or Shaker Table?

|

Eddy Current Probe Gap Voltage Corrections

|